Drone Hive

Drones in Pipeline Inspection

Drones in Pipeline Inspection

Oil and Gas pipelines run for thousands of miles and are subject to vagaries of nature and given their geographical and political importance along with the remoteness of their locations, face risk of damage and/or tampering from outsiders. Also, given the size of the projects and their location, inspection of pipelines has proved to be a difficult task. Undetected leaks have led to damaging fires and explosions, causing loss of life, damage to the environment and economic losses for the operator.

Pipeline networks thus require regular inspection and monitoring. Monitoring of over the ground pipelines require the use of sensors to detect rust or corrosion. If the pipeline is under the ground, there is a need to detect the existence of methane or alteration in the surrounding vegetation that could indicate a potential damage.

Traditional Methods

Traditionally, the oil and gas sector has relied on ground vehicles and manned aircrafts (including helicopters) to detect damages and potential threats to pipelines. The industry is estimated to spend close to $50 billion annually just for monitoring expenses.

For detecting minor leaks from up close, oil and gas companies utilize various technologies like in-line inspection devices (used to assess the integrity of pipelines from the inside), hyperspectral imaging (measuring contiguous spectral bands across the electromagnetic spectrum) and SCADA systems (Supervisory Control and Data Acquisition – control system architecture for high-level process supervisory management).

However, for broader external vulnerabilities, pipeline operators rely on manned vigilance, using aircrafts or helicopters with ‘spotters’ on board (sometimes flying as low as 183 metres), whose primary responsibilities include checking for signs of damage, anything out of place or potential threats like unauthorized use of machinery or construction close to the pipeline. These pilots use pipeline mapping data, cameras and video equipment for surveillance and would contact the pipeline company if they come across potential issues.

The frequency of pipelines survey from the air depends on the size of the pipeline and its contents, is more often than not regulated. Some pipelines need a daily surveillance, while others may require one survey every few months.

Such external inspections are costly, time-consuming and labour intensive. Analysing data collected from various sources proves to be another challenge. Thus, it becomes imperative for pipeline operators to find an efficient and cost-effective maintenance strategy

Where Can Drones Make a Difference?

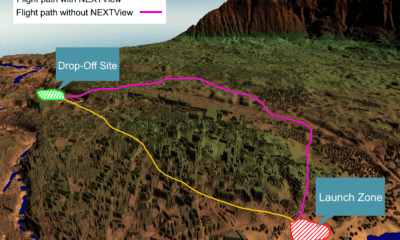

Drones are increasingly being used by pipeline operators to conduct surveying and mapping of pipelines during the route planning process, and once the operations start, right-of-way monitoring and inspection of the pipelines and their surrounding areas. Drones could prove to be an effective alternative, especially for remote or hard to reach areas.

Drones provide significant potential for saving costs through automated maintenance, integrity, and surveillance workflow, and automated data gathering and analysis.

Often drones are used to determine route selection, conduct detailed engineering and construction surveys and ongoing construction surveys (commonly called as-built surveys, showing the current state of the project). The information collected using the drones can be wide ranging – from topography and existence of other utilities in the vicinity to locating the property boundaries and keeping track of construction progress and materials usage.

Drones are being used to conduct thermal inspection of pipelines to detect oil and gas leaks, which can be captured by thermal imaging due to temperature differences between the fluid (oil or gas) and the surrounding soil.

Drones can help in detecting leaks, structural damages, vegetation growth and other potential problems associated with a pipeline. Drones can also detect pitting, a localized form of corrosion causing cavities in the material. Pitting is considered more risky than uniform corrosion because of difficulty in estimation or its detection.

Drones provide additional flexibility in that they can be programmed to cover large areas in a systematic way, while also providing easy reach to difficult to reach areas. All this, while allowing unlimited real-time data collection 24/7, so the pipeline owners/users can focus their efforts (time, personnel and capital) on deeper analysis of the available information. Drones have also proved to be an economical alternative in the area of inspection work.

The Specifics

Photogrammetry – Drone surveys are used to create a three dimensional representation of the surface using photogrammetry. High-tech cameras are used to take overlapping photos to measure the distance between various objects. Drones are also fitted with other sensors (thermal, light) that are used to assess the vegetation along ‘right-of-ways’ and more critically, hot spots that indicate potential pipeline leaks.

Safety and Security – The use of drones in terrain scouting and routing of a pipeline before the beginning of construction allows a detailed study of the terrain without having to send out manpower over an unknown terrain that could pose safety issues. Additionally, this also allows for saving precious time and resources.

Cost Effectiveness – Drones can help in reducing maintenance costs by a significant margin. A drone typically uses 1/100th of fuel in comparison to a helicopter, while also providing a highly economical footprint (ease of shipping and equipment portability).

Production Stability – Drones can be used to avoid unnecessary shut-downs, thereby reducing disruption to operations.

Some Available Options

Canadian company SkyX’s SkyOne vertical-takeoff-and-landing (VTOL) drone was designed for the oil and gas industry, with focus on pipeline inspections, surveillance and mapping. The drone uses a proprietary technology that enables it to recharge itself from the nearest available remote station. When fully charged the drone can fly for 70 minutes at an average speed of 90 miles an hour.

AIR MARINE, a French company conducted the first drone-based gas pipeline surveillance program in France for GRTgaz, a European natural gas transmission company. The project involved surveillance of an 80 km stretch of pipeline on the GRTgaz natural gas transport network.

Conclusion

Drones allow proactive monitoring and inspection of pipelines that are subject to structural damages from corrosion, leaks and surrounding vegetation. Given the safety risk to human resources on account of undetected leaks and remote and dangerous terrains, drones offer a time, resource and cost effective alternative to manned surveillance. Drones allow aerial and thermal inspection of pipelines and refineries without requiring shutdowns.

Drones can easily carry out detection and analysis of hairline cracks, corrosion, spillage and leak detection, thereby improving the overall efficiency of the pipeline monitoring and maintenance process.