News

Ballard Power Systems Develops Advanced Drone Propulsion System

Advanced Propulsion for UAVs

Unmanned Aerial Vehicles (UAVs) are making dramatic changes to many industries. From infrastructure and construction site inspection to agriculture and disaster response, ‘drones’ permit us to acquire and process data faster, with greater resolution, and at a lower cost per hour than ever before. In the future, UAVs will carry out more advanced tasks, such as wireless internet access and package delivery. However, with the growing interest, limitations in the current propulsion systems are coming to light.

Drawing upon a decade of successful UAV fuel cell experience by Protonex Technology Corporation, a wholly-owned subsidiary of Ballard Power Systems, Ballard offers a complete UAV fuel cell solution. Unmanned systems powered by fuel cells operate longer than their battery counterparts, with the same benefits of low thermal and noise signature. Users see improved reliability over small internal combustion engines, providing safe and low maintenance operation.

Ballard has also received a follow-on contract from Insitu, a Boeing subsidiary, for extended durability testing of the next-generation 1.3 kilowatt (kW) fuel cell propulsion system to power test flights of its ScanEagle UAV platform. Ballard UAV fuel cell systems have flown in platforms from Insitu, Aerovironment, Lockheed-Martin, and others. Ballard commercial UAV systems are proven performers: rugged, reliable, and lightweight.

Ballard and Insitu have partnered over the past two years to integrate Ballard’s prior generation fuel cell propulsion system – a complete hydrogen power system for small unmanned fixed wing and Vertical Take Off and Landing (VTOL) platforms – into the ScanEagle platform. Successful flight testing was announced in mid-2017.

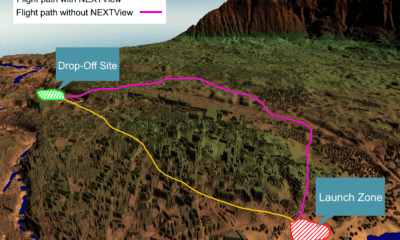

There are several features of hydrogen-powered UAVs that make it the most efficient solution available, namely- Hydrogen is a safe and readily-available energy source; refilling is quick and easy – typically taking less than 5 minutes. It also emanates much reduced noise, compared to internal combustion engines, results in lower acceptable flight altitudes and increasing sensor fidelity. Fuel cells operate more efficiently at high altitudes than internal combustion engines, enabling effective use in mountainous regions. Fuel cells produce no emissions and reduce or eliminate lithium battery disposal challenges and costs. This means extended mission time and distance by thrice the previous capability.

Phil Robinson, Vice President of Unmanned Systems at Protonex, said, “The Ballard and Insitu teams have collaborated closely over the past several years to integrate our proven fuel cell technology into the industry-leading ScanEagle platform. This new fuel cell has the potential to deliver a range of benefits compared to the use of an internal combustion engine, or ICE, to power the ScanEagle. These benefits are likely to include an increase in reliability and available electrical power along with a simultaneous reduction in audible noise, thereby enabling lower altitude missions.”

Andrew Duggan, Vice President and General Manager of Insitu Commercial added, “Insitu is pleased to continue our partnership with Ballard as we add capabilities, further increasing reliability and decreasing operating cost of the ScanEagle platform. We look forward to further performance tests and customer demonstrations in the coming year.”