Drone Hive

Drone Use in Offshore Oil and Gas Industry

Drone Use in Offshore Oil and Gas Industry

With the advancement in drones and related technologies, drones are increasingly finding their way into various capital intensive sectors. One such area is Oil and Gas, both onshore and offshore.

Given the complications and high costs associated with offshore exploration and operations, companies are now relying on drones as a cheaper and effective alternative in helping them overcome some of the regular challenges in the day-to-day operations. So, where exactly and how can drones make a difference in what is considered to be one of the most challenging industrial work environments?

Offshore Oil and Gas Operations

The oil and gas industry is estimated to spend around $50 billion a year globally to monitor pipelines that run up to nearly 10 million kilometers.

One of the major challenges in running an offshore operation is to survey, detect and locate leaks in remote locations. Traditional methods have proved to be both expensive and inefficient, as they lead to shutdowns (causing procedural delays), while the safety of on-the-ground employees also remains a concern, leading to additional cost outlays.

The Drone Advantage

Drones aim to make offshore operations safer and (cost) efficient. The operational efficiency of drones, along with inherent speed and mobility allows for improved surveillance and quick response, while also eliminating the need to deploy manpower in remote and hazardous locations.

The drone infrastructure enables a secure and strong communication network, leading to quick detection and management of issues, at a fraction of the costs compared to traditional methods.

Some of the specific areas where drones are being utilised in the offshore oil and gas industry are:

- security

- monitoring of gas emissions

- detection of oil spill and damages

- offshore oil platform inspections

- flare stack inspections

Security – Drones can provide constant vigilance over offshore infrastructure and assets through an aerial view of the surrounding area. This can be particularly helpful in some of the remote offshore locations, where vessels may face risk of piracy.

Monitoring of Gas Emissions – Various processes in offshore platforms involve the use and production of hazardous combustible, toxic and nontoxic gases. Undetected emissions may lead to depletion of oxygen levels, with serious health implications for nearby personnel. Thus, it is essential to monitor these emissions. The monitoring needs to be fast and accurate to ensure emergency and/or preventive measures can be carried out at the earliest. Gas emissions are even more difficult to monitor offshore. Optical sensors fitted on drones are used to survey and identify leaks.

Detection of Oil Spill and Damages – Firms undertake precautionary measures to prevent contamination in the case of a spill. Drones equipped with appropriate sensors can measure and quantify oil spills with respect to the affected area and the pace of its spread. Information in the real time can help response vessels reach the exact location of the spill, thereby reducing its spread and overall recovery time.

Offshore Oil Platform Inspections – Aerial inspection using drones enables early detection (and thus, repair/maintenance) of structural damage to the pipelines, external or internal variations and other structural abnormalities. Drones can fly close to the affected structure and provide operators with high definition still-images and videos. This allows for proper assessment and planning of repair or maintenance work.

Flare Stack Inspections – The speed and control responsiveness of drones becomes vital in enabling a detailed optical assessment of flare stack heads. The use of drones significantly reduces the risk associated with such inspections by eliminating: i) the need for manpower to climb the stacks; ii) the need to shut down the stacks (for the safety of employees). The latter ensures that there is no impact on the production schedule, saving millions for the company involved.

Challenges

In addition to numerous regulatory requirements on drones, there are other challenges intrinsic to the use of drones. Some of these are:

Network Security – Drones primarily connect to a network through Wi-Fi, which if not properly secured, leaves them susceptible to potential hacking and manipulation. The data on the network and transferred by drones may thus become accessible to a third party. In the worst case scenario, the potential malware may be used to carry out illegal operations.

Scalability – Offshore operations are dependent on a dedicated network. The use of multiple devices may put a load on such a network, with drones using the same network simultaneously as other critical operations. Without a powerful network, it may become difficult to manage operations in a seamless manner.

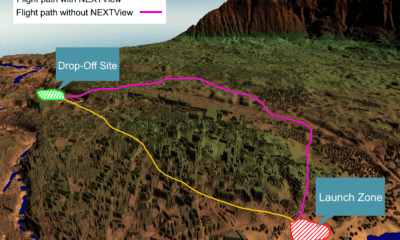

Connectivity – Offshore operations may require drones to provide access to remote locations. Most of these drones depend on wireless connection to communicate and thus need to remain within operability range to maintain connectivity (given the network is provided by fixed infrastructure like cell towers and routers). This creates a major impediment to using drones in remote locations that form an integral part of offshore operations.

The Kinetic Mesh Solution

Recently, the implementation of ‘Kinetic mesh wireless networks’ has significantly overcome some of the challenges described above. These networks are said to be highly secure, offering scalability and mobility, the two primary requirements for a flexible real-time network with no downtime.

The kinetic mesh offers a secure (256-bit military-grade encryption) private network that can detect and prevent illegal access. The network also encrypts the Metadata. The kinetic mesh allows the network to adapt to node locations, building routes automatically even in rugged conditions. The mesh network can be redeployed and expanded, while retaining its reliability. Piloting of the drones may be transferred from one pilot to another in a seamless manner to create a wider network and reach remote offshore platforms or rigs without the use of multiple drones.

The flexibility of the supporting infrastructure allows for an expansive network footprint, an essential requirement for a large-scale offshore operation. The mesh network deploys “multiple, redundant radio frequencies and any-node-to-any-node capabilities” to re-route data in real-time over the best-available path and frequency.

The Future is Drones

Drones are changing the face of the offshore oil and gas industry since 2010. While surveying and monitoring remote (or hard to reach) areas with the help of drones have become an integral part, operators are finding new uses for drones.

One area being explored recently for drone usage is employing remote medics for rigs (enabling on-the-spot medical diagnosis and treatment through teleconferencing with physicians). With the advent of technology like automatic image recognition and search functions, drones are now becoming an essential part of asset integrity management.

With innovations in both drone technology and communication networks, drones are likely to find newer uses, enabling the offshore oil and gas industry to achieve new levels of safety and efficiency.