Deeper Underground with Tilt Ranger Mining Drones, Interview – Pau Mallol, Founder of Inkonova AB

Inkonova is a Swedish startup that develops drone solutions. Based in Stockholm, it started selling mid-2015 utilizing the tilt-rotor systems for racing drones, creating one of the world’s fastest drones and beating a Lamborghini at the same time. The company switched focus to becomes the world’s first developer of drone solutions for underground mining operations. We spoke with Pau Mallol to delve deeper ‘underground’ with Inkonova into the companies past and future directions.

Can you please outline the vision behind Inkonova?

Inkonova’s vision lies in creating products and services that are beneficial for society. For that reason, we started addressing the underground mining and tunnels mapping and inspection, more specifically of inaccessible or dangerous areas.

From racing drones to a mining drone, what lead you down this new path (tunnel)?

A number of reasons. It was a mix of market dynamics in the drone racing market (not really matching our long term vision), the thirst we have for developing new technology and the opportunity we saw in the underground mining market.

- TILT Ranger: The World’s First Solution for Underground Mines and Tunnels

- TILT Ranger: The World’s First Solution for Underground Mines and Tunnels

- TILT Ranger: The World’s First Solution for Underground Mines and Tunnels

- TILT Ranger: The World’s First Solution for Underground Mines and Tunnels

- TILT Ranger: The World’s First Solution for Underground Mines and Tunnels

- TILT Ranger: The World’s First Solution for Underground Mines and Tunnels

Can you describe the Tilt Ranger, and the markets it serves, benefits etc?

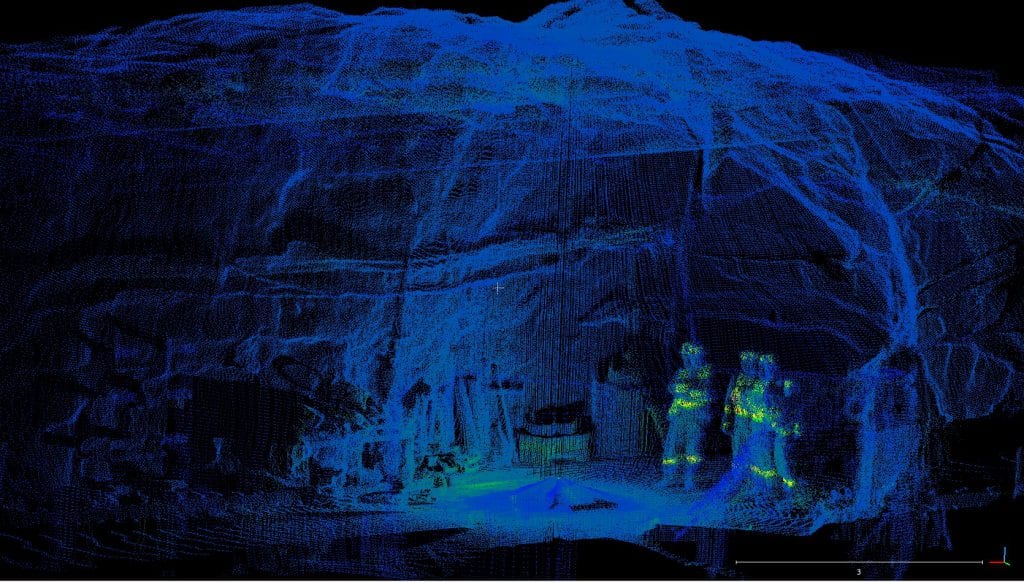

The TILT Ranger is a drone particularly suited for underground areas like mines and tunnels. It has been developed to be compact yet with high payload capacity thus, able to carry a full 3D lidar system. It also features our dynamic tilting arms technology we developed first for the drone racing market but that it turned out to have more value for industrial drones like the Ranger. Tilting the arms provides several advantages like the fact we can hover and fly at different body angles or roll on ground.

What were the challenges faced when developing Tilt Ranger?

The most relevant challenge was to reach a trade-off between overall drone size, payload capacity and flight time: I call these the ‘triangle of pain’ or ‘triangle of hell’ because these three variables pull on opposite directions and, in our case, the requirements we had made this problem very hard to solve (and still improving the system).

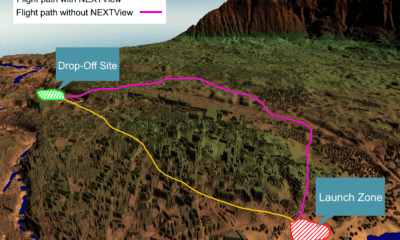

What’s the Tilt Rangers’ range from operator and other specs?

It is a very common question we receive but very hard to answer since, underground and beyond line of sight, every case is different. What I can refer to is to past experience: We have been able to fly during our tests in Sudbury, Canada, up to 200 meters beyond line of sight. Other tests in a test mine in Sweden gave us 120 meters range beyond line of sight. Communication is the main issue today since we are automating the whole flight and scanning but we still need to receive telemetry and the area’s map in real-time.

Have you conducted any field trials and if so can you tell us a more about them?

Yes, plenty. As mentioned, we flew in LKAB’s mine in Kiruna (Sweden), the largest and most modern underground iron ore mine in the world, Boliden’s mine Garpenberg, Sweden’s oldest mining area that is still in operation, NORCAT test mine in Sudbury (Canada) and others. It is also worth noting that we also demoed our product in the past in Mali, Peru and Argentina.

Are these units in production and for sale?

Yes they are. We sold the first Ranger in 2016. However, we do have also today a smaller TILT drone for visual inspection (TILT Scout) and the autonomous, laser-based, mapping drone system called Batonomous. You can find more information on these in our website.

Are there any early adopters of your product you can talk about?

Clickmox Solutions Inc (Canada) would be a good example.

Do you see opportunities in other industries for the Tilt Ranger or variants of?

Yes. We are actually partnering with a Norwegian company to address the oil and gas and other markets.

You have a 3D printing background, any elements created using this technique?

Yes, plenty! 3D printing is a great tool for developing fully functional prototypes and systems when structural properties and look are not a priority (although some 3D printing technologies and materials do provide today a great appearance and mechanical properties). We still use some 3D printed components, for instance with the latest Nylon materials for covers for instance: tough and a nice matt black look).

What is next on the horizon for Inkonova?

The immediate goal is to commercialize our Batonomous drone system for autonomous mapping, later this year (summer/autumn). We have successfully tested a prototype of the system in front of a few close clients and they love it plus it is extremely easy to operate (no drone flying experience required). However, the drone platform has to be upgraded and this is what we are working very hard on. Later, we expect to build a couple of prototypes of the new system we are conceptualizing for the oil & gas, maritime and tank inspection markets.

Inkonova is developing an autonomous navigation system for aerial drones to operate in unknown zones without any touch of infrastructure; no GPS, light or any installations. Ones akin, but not limited, to underground mines.

Overall how do you see the drone technology expanding or changing in the next 5 years?

I think this Q1-2018 the drone market has reached a point from where autonomous and AI drone technology* will accelerate its development and applications. Look at the Skydio R1, a truly revolutionary system. That means that we are much closer to be able to use drones in areas where they have to interact with humans, animals or cluttered spaces (past products were not as robust as Skydio in my opinion).

* I use to differentiate from other autonomous technologies like automotive, since mass and volume requirements on hardware and dynamics differ significantly from those in drones.

The next 20 years?

I think the technology and application leaps will occur until 2023-2025. From there it will mostly be spreading out drone applications and incremental improvements. However, I think that by 2030 we should have a radically different propulsion system (including energy source) for aerial platforms, something radically different from what be have now.

In the drone/UAV industry what companies excite or inspire you?

Cyberhawk, Spotscale and Flyability.

From Barcelona to Stockholm, how did that come about?

I discovered Scandinavia in 2006, living in Erasmus, Finland for 6-months, as part of my degree. After that I returned to Barcelona and started working in a large company, I soon felt I needed to go abroad again to study and seek one of my passions: Space. I found the Aerospace Master programme at the Royal Institute of Technology (KTH) and Stockholm to be what I looked for so I moved here. Then I just got naturally entrenched in Stockholm with a research engineer position at KTH, wife, PhD, kids and of course Inkonova!

About Pau Mallol

Mechanical and aerospace engineer with three degrees: Mechanics (UPC, Spain), Aerospace (KTH, Sweden) and Licentiate in structural mechanics (KTH, Sweden). Pau has a long history of technical developments in the field of 3D printing, mechanical and aerospace areas and multi-faceted edge on all UAV design aspects, electrical, mechanical, aerodynamic, communication and coding. He also have an extensive academic circle in KTH Royal Institute of Technology through his studies, research and consultancy work which tapped different scientific areas. Driven, goal-focused, like challenges and continuous professional development.

Mechanical and aerospace engineer with three degrees: Mechanics (UPC, Spain), Aerospace (KTH, Sweden) and Licentiate in structural mechanics (KTH, Sweden). Pau has a long history of technical developments in the field of 3D printing, mechanical and aerospace areas and multi-faceted edge on all UAV design aspects, electrical, mechanical, aerodynamic, communication and coding. He also have an extensive academic circle in KTH Royal Institute of Technology through his studies, research and consultancy work which tapped different scientific areas. Driven, goal-focused, like challenges and continuous professional development.