News

World’s Largest 3D Printer Prints 1.8 Metre Titanium Drone

Australian advanced manufacturing company Titomic has delivered the largest titanium 3D printed drone or unmanned aerial vehicle (UAV) ever made, measuring more than 1.8 metres in diameter.

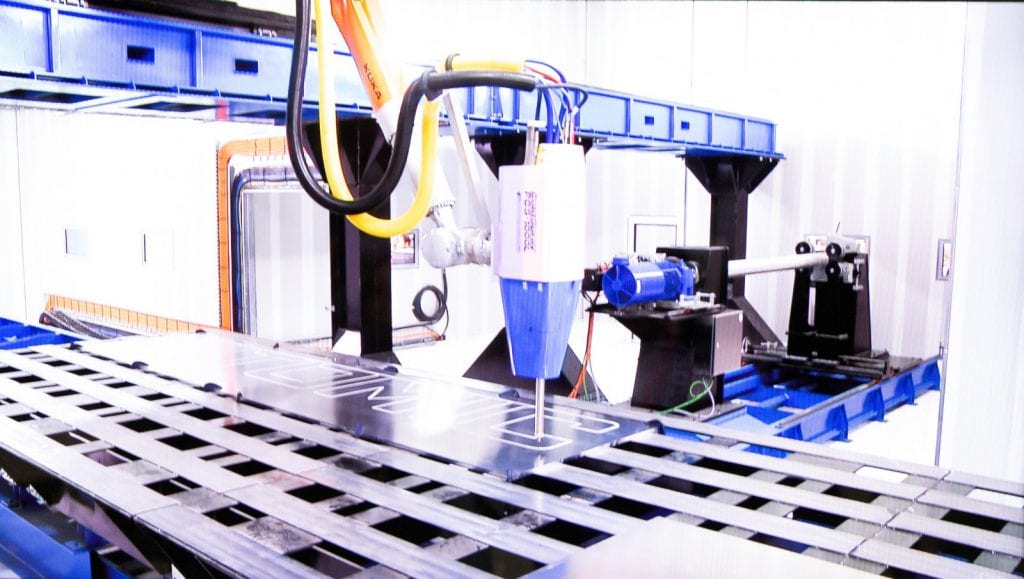

The UAV was manufactured at Titomic’s R&D Bureau in Melbourne, home of the world’s largest and fastest metal 3D printer. Reports from Defence Connect amongst others said that the quadcopter UAV was delivered to an unnamed client, and was printed on Titomic’s TKF9000 machine, which has a print bed of 9 x 3 x 1.5 metres. According to Titomic, the titanium structure offers a rugged and lightweight design, and the craft is “well-suited for deployment in live combat situations.”

The system incorporates Titomic’s patented additive manufacturing technology, Titomic Kinetic Fusion. Titomic uses a cold spray-based method it calls TKF to fuse metal particles, and was spun out of the CSIRO.

The technology, co-developed with and licensed from the CSIRO, is a patented metal additive manufacturing process utilising supersonic deposition of metal powders to digitally manufacture metal parts and complex surface coatings of super alloys and dissimilar metals such as nickel, copper, scandium and alloys such as stainless steel, inconel, and tungsten carbide. Titanium, with its superior strength-to-weight ratio, provides the UAV with a strong yet lightweight and ballistics protection, which will provide durability for reliable in-field use by military and law enforcement.

The prototype demonstrates Titomic’s ability to utilise titanium in applications that previously did not overcome a cost-benefit analysis, forcing manufacturers to use lesser desired materials in design, such as heavier metals or fragile plastics. Titanium’s use is often prohibitively expensive and difficult to fabricate using traditional methods the technology is widely applicable to the defence industry and can also create parts such as armaments, traditionally created through metal casting, resulting in reduced production time and increased output.

Titomic Managing Director Jeff Lang stated: “We’re excited to be working with the global defence industry to combine Australian resources, manufacturing and innovation which will increase our sovereign capability to provide further modern technology for Australia and its defence force”.

Boeing contract

Titomic also announced its deal inked with Boeing to deliver additively manufacturing test parts for airplanes. This initial agreement is for $170,000 for test parts.

Titomic’s shares were up as much as 6.5% to $2.58 in trading this week.

Jeff Lang, appeared to be very pleased with the agreement and sees a major opportunity for the company, stating, “Titomic is pleased to announce this trial agreement with Boeing to deliver additively manufacturing test parts for airplanes. Currently, with traditional manufacturing process, there are up to an 80% material waste and 6-month lead time to CNC machine these parts. These Titomic Kinetic Fusion (TKF) produced parts will allow Boeing a significant reduction in lead-times, improved performance for composite part production and cycle times.”

If the trial is a success and Boeing extends the agreement, it could prove to be a game-changer for Titomic.