Back to Base (B2B)

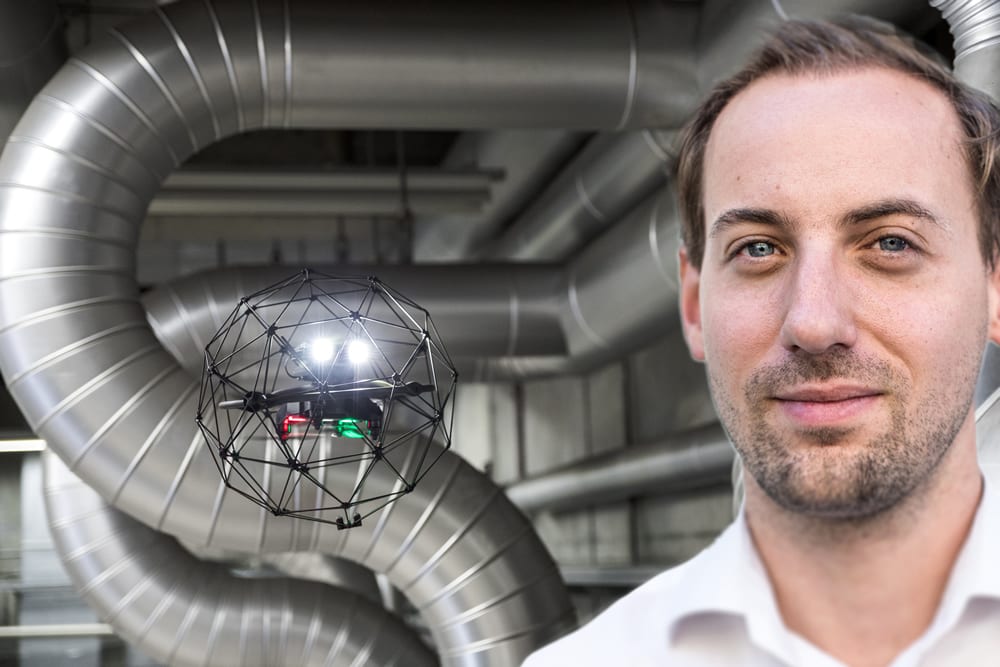

Safe Drones for Inaccessible Places: Interview with Patrick Thevoz, CEO Flyability

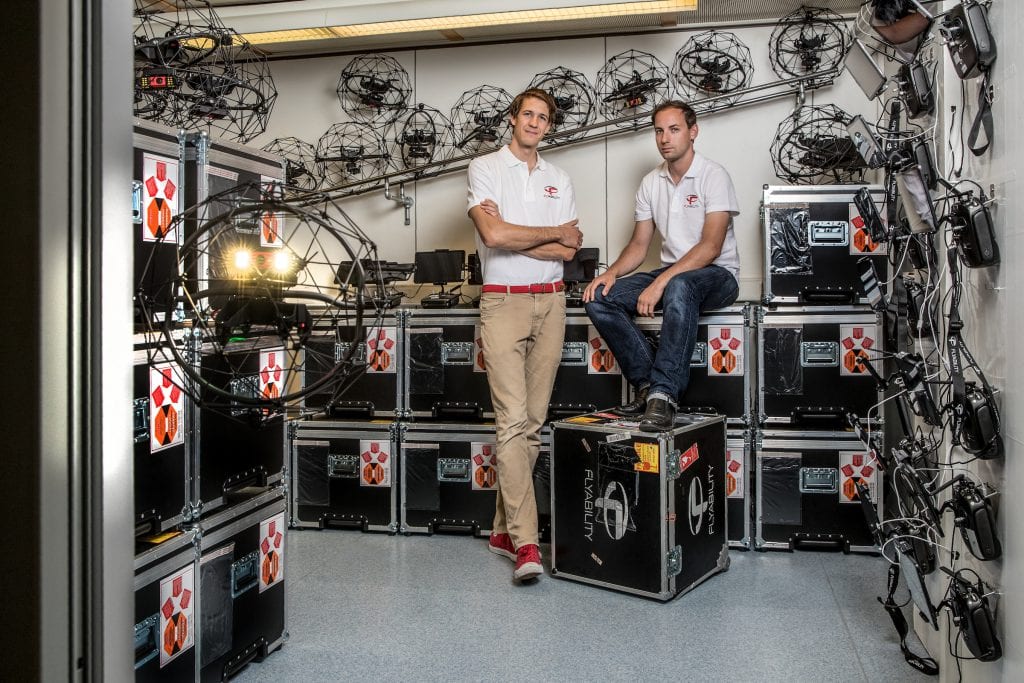

A design inspired by insects, with the strength taken from the covalent buckyball – it’s a drone that is seeing Flyability founders Patrick Thevoz and Adrien Briod make an impact in more ways than one. Here we speak with the engineering graduate from EPFL and Flyability CEO about how their cage-like industrial inspection drone has found a way into and out of tight situations, all while reducing risks and improving efficiency.

The concept behind the Elios is inspired – how did Flyability get started, and how was the idea generated?

Flyability started as a PhD thesis at EPFL in Switzerland, as my co-founder Adrien Briod was looking at ways to send robots instead of humans in dangerous situations. During the PhD thesis, disasters such as Fukushima and the Haiti earthquake shook us and made us focus on indoor, confined spaces.

Patrick Thevoz (right) and Adrien Briod (Left) Photo courtesy of Flyability

The challenge of flying in such complex places was solved by looking at how insects fly indoors: despite sensing their environment, they are able to collide in flight and recover instantly, using this feature to navigate in complex space. This is what we replicated in our first product, Elios.

- Flyability Elios in Action 67 – Operator

- Flyability Elios Jack Up Rigs Inspection

- Flyability Elios Maritime | Rims

- Flyability Elios in Industrial Action

- The Flyability Elios

Photos courtesy of Flyability

How does Elios revolutionize the concept of inspection drones?

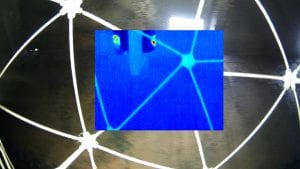

Elios is unique in its ability to fly in indoor, confined or complex spaces. As it can safely collide on obstacles, navigate in spaces as small as 40cm, and is able to gather visual inspection data from pitch dark environments. This enables to perform inspections in places such as power plant boilers, tanks, chimneys, ducts, and basically any place inside a factory, where no other drone or robotic solution can access.

How is Elios helpful in increasing work efficiency and reducing downtime?

By using Elios, you care reducing or even removing the need for scaffolding, rope access, and other complex and expensive lifting equipment. As a reference, the complete staging of a power plant boiler can cost up to USD $100,000! You are also removing the need to send people inside a confined space, which is a huge safety risk: over 200 deaths per year happen in industrial confined spaces.

And finally, as you are able to get the data you need faster, you can bring the asset back online sooner, resulting in huge savings. Some of our customers have reported they have saved over USD $500,000 on a single use of Elios!

What kind of data do you provide post mission?

With Flyability Inspector, our post-mission software, you can review all the images, thermal images (we have a FLIR camera on-board) as well as sensor data such as the altitude and heading of the drone. You can then edit and annotate the points of interest of the inspection, and export it to an inspection report instantly.

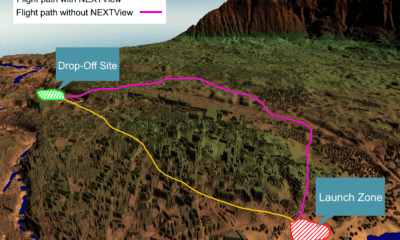

Elios can be controlled in a wide 5km radius, which is quite a feat. Which technology are you using for wireless transmission and is it safe to use within that range?

Flying indoors is a big challenge in terms of transmission. We have partnered with drone market leader DJI to provide a high-performance digital transmitter on the 2.4GHz band which handles reflections in metallic environments and beyond-line-of-sight situations very well.

The actual recommended range will depend on what separates the pilot from the drone. 90% of our work involves ranges of about 100-200m only, but require a high reliability of the signal.

- Flyability Elios Special Forces

- Flyability Elios in a Glacier

- Flyability Elios Firefighters | SITM Plzně

- Flyability Elios in Action – Public safety

- Flyability Elios in Action – Public safety

- Flyability Elios in Action – Glacier

- Flyability Elios in 2015 Gimball

- Flyability Elios

- Flyability Elios

Photos courtesy of Flyability

The structure for protection looks similar to a buckyball, is there a relation to that at all?

Indeed! We are using high-performance carbon-fiber composites to build the protective structure, which is able to handle very strong collisions. Using this structure enables to maximize the rigidity of the protection and take best advantage of carbon fibers which are amazingly strong in traction, but weak when bent.

The Elios is designed to recover its path post-collision, but are there any plans to introduce AI to Elios to give prior warning to hazards?

Absolutely. Again, looking at inspiration from insects, the combination of collision-tolerance and obstacle avoidance and SLAM (simultaneous localization and mapping) is the key for those complex environments. Our team is continuously working towards making our drones smarter and more autonomous.

What is the flight time of the Elios? In case of longer duration of inspection how can one change the battery whilst inspecting dangerous areas?

The typical flights last about 10 minutes per battery. Five batteries are provided with each drone purchase, and batteries can be swapped in seconds. As we are usually operating at fairly short ranges, it is easy to bring the drone back to the operator base, swap the battery for a full one, and get back to flying and inspecting.

- Flyability Elios Boiler Picture 5 – © SITM Plzně – Tušimice

Photos courtesy of Flyability

Up to what extent is the Elios collision tolerant ?

It can tolerate collisions at about 15km/h on any type of surface.

What temperature range Elios can sustain?

We recommend using Elios between 0 and 50 °C.

Is the Elios water-resistant? What measures have been in put in place to protect it from electronic damage in case of exposure to water?

Elios is resistant to humidity, water projections or a light drizzle of rain, but will failed if it is immersed in water. Elios is built with our target applications in mind and it is very important for some of our customers inspecting maritime assets such as ballast tanks to have a drone able to resist the presence of water.

What industries are you targeting now, and do you have your eyes on any other sectors?

We are working in Power Generation, Oil & Gas, Mining, Chemicals and the Maritime industry. We also have multiple police forces and firefighter brigades using our product, in about 10 countries. We are discovering new use cases every days with our customers, we started for instance this month working in the food & beverage industry for the inspection of large tanks at a brewery!

Where are you at in the production stage?

Elios is now produced in series, after 10 iterations of prototypes throughout 2013 – early 2017. It has been a long journey to get to the very high reliability and repeatability that we are striving for!

We heard about your partnership with Blue Innovation. What are your expectations with this?

We are working with over 30 partners worldwide to bring Elios to market. In addition to our internal sales team, local partners such as Blue Innovation in Japan are instrumental to develop regionally new business, train customers, and provide a local point of contact for our customers around the glove.

In Australia, we are working notably with Riseabove (www.riseabove.com.au), one of the largest drone resellers in Australia, and Austeck (www.austeck.com). They have units in stock and are able to perform demonstrations to our Australian customers.

You have already raised ‘Series A’ Round of investment in 2016. What’s your next target?

Fundraising is not a target per-se for us, our goals is to continue leading the indoor drone inspection market we pioneered, in order to keep removing people from dangerous situations and deliver increasingly high return on investment to our customers. In terms of fundraising, we are opening now a new round of financing.

Where do you think the UAV market will be in the next 3 years?

While the consumer market may start to saturate in a few years, the opportunities in commercial applications are huge. We estimate the market for our solution at over 3bn USD, the road to a wide spread adoption is still long, but with over 9/10 customers satisfied and huge returns on investment achieved, we see UAV solutions becoming the standard for visual inspections in some environments in a very short time.

Where do you see your Elios in next 10 years?

Elios is continuously improving, towards a smart data acquisition and analysis platform. In 10 years, the drones themselves should be automated in such a way that we will require no pilot, and customers won’t have to care about the drone itself, so they can focus on the business outcomes which will be automatically analysed from the gathered data. The press of a button is going to be all it takes to get a digital twin of any asset, with all defects automatically identified for the engineers to take action!

About Patrick Thevoz – CEO and Founder at Flyability

Patrick is Co-founder and CEO of Flyability, the leading professional indoor drone company aiming at increasing efficiency and reducing risks for humans in industrial inspections. Under his tenure, Flyability grew from 2 to over 65 employees and acquired over 300 customers. Before founding Flyability, Patrick worked as a strategy consultant as a specialist in product launches for the life sciences industries. Patrick graduated from EPFL in Switzerland with an MSc in Engineering.

Patrick is Co-founder and CEO of Flyability, the leading professional indoor drone company aiming at increasing efficiency and reducing risks for humans in industrial inspections. Under his tenure, Flyability grew from 2 to over 65 employees and acquired over 300 customers. Before founding Flyability, Patrick worked as a strategy consultant as a specialist in product launches for the life sciences industries. Patrick graduated from EPFL in Switzerland with an MSc in Engineering.