Houston Mechatronics Dives Deep, Transforming Underwater Autonomous Robotics with $20M Funding

When we think of autonomous robots the first thing that springs to mind is more than likely something out of 1960s science fiction – a humanoid helper perhaps, or a mechatronic arm in a factory.

As for underwater autonomous devices? We’ve written about quite a few drone makers who have dived into the field of unmanned underwater vehicles (UUVs) – BlueEye, Aquabotix, and Allec to name few – but they are namely that, the marine equivalent of their airborne equivalents, UAVs.

These UUVs mostly traverse the undersurface of the waves and are often tethered, providing the device with unlimited power and the pilot with immediate access to data and imaging.

Deep sea, a frontier as inaccessible as space itself, remains the territory of gas and oil exploration behemoths, the military and science.

Now, USA-based Houston Mechatronics are taking undersea robotic autonomy to new depths – so deep in fact they say their hybrid UUV robot will dive as deep as 3,000 metres.

Called the Aquanaut, the versatile deep sea robot is the result of a development team made of a team roboticists from NASA’s Johnson Space Center. HMI formed in 2014, driven by CTO Nic Radford, previously chief engineer on the Robonaut project and head of the Valkyrie development team.

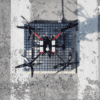

- The HMI Aquanaut in WorkClass mode | HMI

- The HMI Aquanaut in Excursion mode | HMI

Getting to the bottom of the ocean is no mean feat, and the HMI team have surmounted huge challenges to achieve their subsea goals. To top it off, they’ve also announced a boost to their development efforts with a very impressive $20 million Series B funding round.

Up until now, any research or exploration conducted at any significant depth is done by use of tethered ROV, that is submarine robots that require human manipulation and support vessels to operate. The exorbitant costs of missions using these ROVs mean the technology is really only available to organisations with access to large funds.

The Aquanaut is HMI’s answer to this problem. By coming up with a patented design that frankly, is reminiscent of the Transformer toys from days of youth, the Aquanaut starts its deep sea journey as a pod-like UUV in what they refer to as ‘Excursion Mode’. On arrival at its destination, the Aquanaut shape-shifts into ‘WorkClass Mode’, opening to reveal two robotic arms that it can use to manipulate objects using a combination of autonomous programming and remote-control.

Transformation of the HMI Aquanaut | HMI

Speaking with IEEE Spectrum, Radford explained thinking behind the technology that allows this untethered autonomous approach to work.

“One of the particular skills that we had developed at NASA was centered around this major concept: dexterous mobile manipulation in really crappy communication environments,” he said.

“In spaceflight, communication to remote assets like robots can be fairly intermittent, slow, latent, and lossy. Just like space, remotely operating robots underwater involves dealing with major uncertainties in the robot’s action. Therefore, optimizing the transfer of information from operator to the robot for action and having the robot understand the intent of an operator’s command is critical. The robot can then plan that action, execute it, and confirm its success back to the operator.”

However the acoustic communication method that the Aquanaut uses has limits, at most ten kilobytes per second. To counteract this, HMI developed a system called ‘assistive autonomy’, whereby pre-programmed building blocks allow the Aquanaut to function with a minimum of commands from the human operator.

Houston Mechatronics CEO Matthew Ondler says the technology will revolutionise subsea aquatics. “Aquanaut, and our tightly coupled over-the-horizon software Commander, enables Houston Mechatronics to deliver more feature rich, safer subsea services to commercial and defense customers that demand it,” he said.

“Our team developed some of the most advanced robots that NASA ever produced and has been developing advanced subsea robotics technology for confidential customers for years. Aquanaut represents the pinnacle of our company’s expertise and experience and we are beyond excited to introduce this vehicle to customers.”

What does this mean for the future of unmanned robotics in general? The patented system is sure to see HMI secure a position as a serious player in marine-related industries, be it industrial or military.

“We have removed the need for onsite vessels (and people) from subsea work while still maintaining the operator’s situational awareness and the ability to modify missions, which our customers demand. Our capability can truly transform industries. For the warfighter, this means increasing the standoff distance therefore resulting in safer conditions. For commercial customers, this means that we can provide more capability than they have today for much less cost,” said Radford.