AI

Supply Chain Automation – Self-Driving Trucks to Delivery by Drone

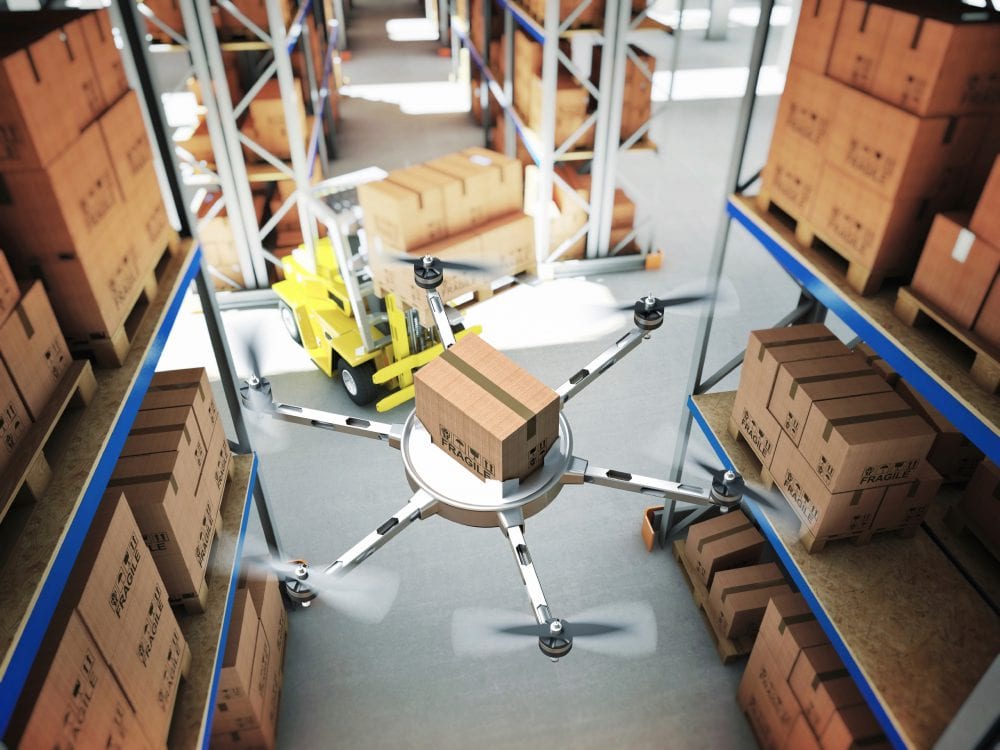

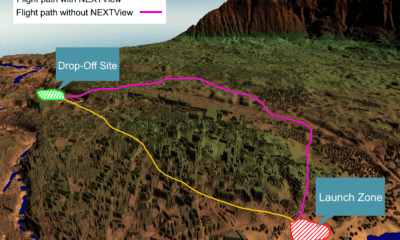

In Australia, as in the U.S., supply chains are already embracing a far greater automated future in order to respond to the increased demand driven by the immense scale of manufacturing operations. The supply chain is already becoming increasingly automated with drones commonly used for delivery and self driving trucks.

The use of automated technology in delivery for the last or final stage of the supply chain has received much publicity in the media, but it is possible that other supply chain areas is where robotics will present the most opportunities.

According to a recent U.S. report many businesses are already eagerly adopting smart machine technology and are significantly increasing their spending on such innovative developments.

The report mentioned in the The Wall Street Journal suggests that 35 percent of supply chain managers have already adopted robotics and the expectation is that this figure will rise to 74 per cent in the next six to 10 years.

According to a report from Colliers International the future size of an industrial warehouse in a major Australian city is predicted to be 200,000 square metres, In contrast, the Melbourne Cricket Ground is 20,000 square metres!

The many benefits to supply chain automation are clear and many suppliers are eager to embrace the new technologies; however such new technologies also present new safety implications and concern over how safe robotics are in the workplace has to be considered.

A report in 2016 (The MHI Annual Industry Report) found that automation capabilities had become safer and more efficient with the introduction of safety barriers and sensors prohibiting people from working too near the machines.

This measure fulfilled occupational health and safety requirements, but it created supply chain inefficiencies – if a package was upside down, workers were unable to get close enough to place it right side up. This has been resolved now with innovations such as robots with “3D vision” and artificial intelligence, not only reducing such errors, but also increasing the safety of workers.Nevertheless while supply chain technologies are safer than they once were, they are not without their hazards and robotics are unlikely to completely replace humans in the supply chain structure, and with humans working alongside robots, safety remains paramount.

The US Occupational Safety and Health Administration (OSHA), has identified seven hazards associated with robotics in the workplace. OSHA says by pre-planning the management of the supply chain by ensuring employees receive appropriate training, a number of potential issues can be avoided.

These include programming mistakes and incorrect activation of the control panel. However, The OSHA says one of the biggest problems arises when an individual becomes over-familiar with the robot’s redundant motions and then puts themself in a hazardous position while maintaining or programming the robot.

Other issues revolve around control errors such as software issues, electromagnetic and radio-frequency interference, as well as faults in the hydraulic, pneumatic or electrical sub-controls, which can create significant danger for workers.

Unauthorised access must be avoided and discouraged at all times because the person involved may not be familiar with the safeguards in place or their activation status.

The possible failure of a mechanical part, faulty or unexpected operation too must be considered.

Other influences such as electromagnetic or radio-frequency interference could also affect the operation of the robot raising the potential for injury to anyone working in the vicinity.

The OSHA warns that other risks can be created by power systems when malfunctions in pneumatic, hydraulic or electrical power sources occur which raises the fire risks;lectrical shock and release of stored energy from accumulating devices also can be hazardous to personnel.

OSHA asserts that hazards are created when employees do not properly follow the design, requirements, and layout of equipment, utilities and facilities of a robot or robot system.

The Robotics Industry Association (RIA) also says while there are in excess of 1.5 million industrial robots safely operating in factories worldwide,” with an “impressive safety record”, it also recognises that “robots can be dangerous to operate”.

The RIA says that in order to mitigate that risk, safety protocol must be adhered to; while robot safety standards are still evolving and will do so as the global market for industrial robots grows and changes, the RIA says it believes that adoption of international standards possibly under the auspices of such as of the International Organization for Standardization, will help ensure improved levels of safety.

While we contemplate whether automation is actually safer and recognise that there are dangers associated with robotics, many believe that automation in supply chains can actually make workers safer.

Deloitte says robotics can “reduce the risk of employee injury in dangerous environments” and as autonomous robots become more sophisticated, they need less supervision, and are able to work side by side with their human counterparts.

Deloitte suggests the benefits are expanding as autonomous robots become capable of working independently around the clock with more consistent levels of quality and productivity, performing tasks that humans cannot, should not, or do not want to do and in situations where dangerous or high-risk tasks are called for. Putting a robot instead of a human in harm’s way makes sense, allowing people to move to more strategic, less dangerous, and higher value work.

As the market for autonomous robots grows, the end-to-end supply chain operations alignment will become more fluid. At present, many companies use autonomous robots for targeted functions in the supply chain, piloting various robots to verify gains, but as innovative companies emerge and expand operations, robots that build robots could be one of the future trends in supply chain, becoming the norm for optimizing manufacturing operations.

Reference: Adapted from CeMAT Insider